The blue Desert Sled was an exercise in creativity and pushing the envelope of form and function. We wanted to see how far we could go when building a simultaneously beautiful and functional Sled. The donor bike, although looking great, had been restored with a paint brush and was in a terrible condition under the new black paint. We decided to give it a new lease on life as it had obviously served someone well. We decided to give this bike the best of everything while still staying as true as possible to the original idea and soul of the W650.

The first step was to address the failings of the bike, and this is said with love, there is very little wrong with the W650 from stock. Two things that need sorting on the W650 from the factory, the brakes and the suspension. The standard suspension is acceptable at best and the brakes are dire. As part of this project, we developed a Big Brake Kit for the W800/W650, our test mule did the graft and the Desert Sled got the results. The brakes were sorted with a custom offset, 300mm floating disc. The caliper is a custom built 6-piston billet piece from Harrison. The Master Cylinder is a 14mm K-Tech unit. The change in braking feel and performance is phenomenal, one or two fingers and a fantastic progressive feel to the braking. We usually use a 17mm Nissin Radial Master on kits we sell as these match the bikes and are plug and play, but the K-Tech suited this bike much better. You can see the fins machined in the caliper to match the Master Cylinder.

The front suspension is normally fixed with progressive springs and a change in oil weight but we wanted to go further. Grafting a GSXR front end on and calling it a day would be the easy way out, but we wanted to do it right. We shaved and polished the fork lowers and installed an Andreani cartridge kit, adjustable for rebound, compression and sprung correctly for the bike and rider’s weight. The top caps were re-anodised silver to match the rest of the front end as the Andreani ones are grey/yellow. The rear suspension was a much simpler option, Hagon made us some custom length shocks with billet tops to suit the bike. The shocks are 25mm longer than standard and the forks have been dropped 25mm with a machined top and bottom triple set from Fastec. This has the obligatory Motogadget speedo integrated into it.

The bike had to feel solid, having ridden a few Triumph scramblers, they have always felt a little ‘spindly’ with the 22m handlebars. To avoid that and give the bike a sturdier feel, we used a set of 25mm Western handlebars with 2 inches cut off. Perhaps they were meant for a Harley but were way too wide, but after being trimmed, they look the part perfectly. To keep the slim looks that a Sled should have, all the wiring is internal and some fancy micro-switches keep it all neat and tidy. The headlight is a perfectly egg-shaped Motodemic unit which complements the lines of the tank and mudguards.

Next up was the tank, most of the retro bikes have these horrible tank seams, that had to go. I was going to cut and weld it, but decided on weld-filling the seam to retain the straight tank and seat line. The fuel cap was cut out and patched and replaced with a flush fitting aero cap to keep the lines clean. The tank came out perfectly, with the knee pads removed and the gold stripes against the blue, it really does cut a lovely and lean shape. When you look at the bike from above the seat and tank narrow into a waspish waist in the middle.

The frame was stripped, chopped, de-bracketed and then polished, Copper-plated and finally Nickel-plated. We’ve always loved the look of the Rickman Meitesse scramblers with their Nickel frames, so decided to do something similar. The rear subframe was chopped and an integrated luggage rack welded on. The vertical subframe needed to follow into the luggage rack, because lines are everything. The same goes for the machined billet swingarm, the triangular shapes that have been machined out match with the triangle formed by the shock, swingarm and frame. Anyone else slightly obsessed with symmetry/asymmetry?

Wheels were straight forward, hubs blasted and polished and re-laced Aluminium Morad rims in 19×3.00 for the front and 18×4.25 for the rear. The tyres are Continental TKC80, one size larger than standard, 110/80R19 in the front and 140/80R18 for the rear. We could have gone wider on the tyres, but prefer the handling to be light and with the over-sized rims the wheels look fantastic.

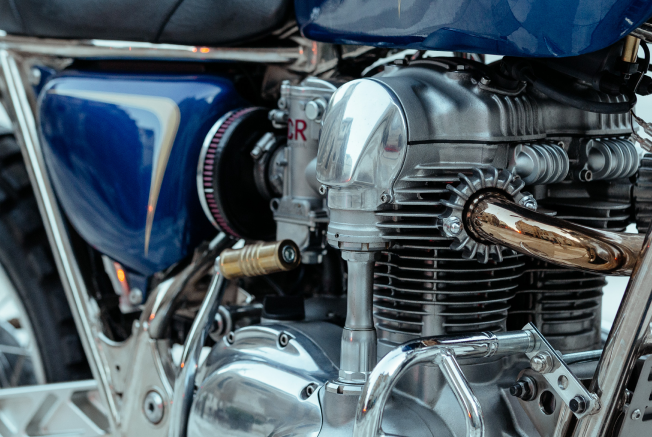

Lastly, the engine was cleaned and polished. Some Keihin CR Special carbs grafted on and some polished stainless shotgun pipes to suit the Sled ethos. The pipes are straight through and yes, it’s loud, but sounds glorious with the 360-degree cranked twin of the W650. There’s a lopey popping idle which turns into a roar at full chat and a rasp on the over-run. Stainless Steel was used for the exhaust pipes as it turns gold with the heat from the engine. This compliments the warm tone of the Nickel frame and the brass highlights on the bike. Believing that less is more when it comes to brass on a bike so we kept it simple, brass clutch register, brass kickstart lever and brass exhaust tips. Just enough. With the CR Special carbs the throttle response is instant and the bike just wants to go. We had considered punching the engine out to 854cc but these engines are just so brilliant as is, all you need to do is let them breathe.

Our goal was to build a Desert Sled with modern handling for comfort and performance, it needed to be reliable and fast. We wanted to do this while maintaining the 60’s style and have a clean and polished finish to it. Everything is done slowly and meticulously, every nut and bolt was agonised over and there were a few changes in direction but in the end, we achieved our goal; a close to perfect modern Desert Sled.